The safety of a nuclear plant is determined in part by the safety culture of the organisation. At EPZ, we work safely or not at all!

Both the plant and the organisation are continually improved.

Safety evaluations every ten years ensure that safety at the nuclear plant remains up to standard.

Nuclear plants learn from each other, at an international level.

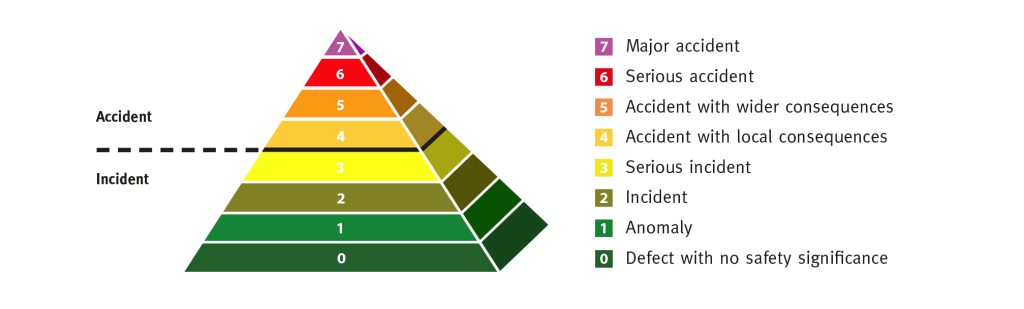

Incidents are always reported and categorised using the INES-scale

Besides nuclear safety, we also focus continually on industrial safety. This includes (personal) qualifications, competences and training.

This video of an operations team being trained in the plant’s simulator gives an impression of what this involves.

Staff performance is continually improved using Human Performance techniques.

Risk and safety

The terms ‘risk’ and ‘safety’ lie at the core of our safety culture. At a nuclear power plant, risk comes in the form of the chance of dying or falling ill due to exposure to radiation. We seek to constantly reduce this risk by continually reducing the chances of exposure to radiation.

The industry, the government and scientists all make huge efforts to achieve this, using a whole range of measures: legal, technical, infrastructural and behavioural. The driving force behind this is risk tolerance (how much risk do we want to accept?) and risk perception (how do we view the risks, or how do we perceive safety?). These are dynamic factors, subject to constant change.

For an example of changes in risk tolerance, we need look no further than road safety. Major risks that were regarded as normal in the past are now no longer acceptable. In 1972 there were 3000 road deaths a year. Now there are around 650, even though there is much more traffic on our roads. Reduced risk tolerance has been the driving force behind measures that continually reduce risk.

Just like on our roads, risk tolerance in respect of the nuclear industry has steadily declined continually. This has prompted us to continually improve safety at our nuclear plant. Over the years, society has come to regard safety associated with nuclear plants differently. The need for measures to reduce risk is driven not only by the potential number of victims, but also by the impact on society as a whole. An accident at a nuclear plant may not disrupt society, or lead to unacceptable economic and environmental impacts.

Technological progress has had a positive impact on safety. Advanced sensors and data communication have made road traffic safer. Things like seatbelts, airbags, movement sensors, design changes, GPS and other forms of communication have improved road safety over the past few decades. Because our risk perception has also changed, we no longer feel safe in a car built in the 1960s that does not have these features. In the same way, the safety of the nuclear plant has grown as the public interest in reducing risk has grown.

Under pressure from growing safety awareness, technological advances and experience have been fed back into the nuclear plant for decades, reducing the risks step by step. Safety is never ‘finished’, and can always improve. At EPZ we call this ‘continuous improvement’. The result of this process can be seen in the development of the EPZ organisation and the layout of Borssele nuclear power plant. Safety has increased at all levels. The organisation has grown from approximately 130 staff in 1973 to some 350 now. Many of these extra employees work on safety at the plant: more analysts, more specialist technical support, more firefighters, larger operational teams etc. All these staff have to meet much stricter training and qualification requirements than in the 1970s.

The layout of the plant has also changed radically over the decades, with the introduction of redundant systems, new barriers and safety systems. If one safety system fails, an extra system will take over.

Thanks to all the physical and organisational measures, the chances of a nuclear incident that impacts on people and the environment have been reduced by about a thousand times over the past 40 years.

The international nuclear community is highly focused on sharing knowledge. The philosophy is to learn as much as possible from the experience of others. Operators share details of best practice, and of technical faults and incidents. News services play an important role in this process, and large numbers of nuclear experts attend international conferences in their field.

EPZ participates in all initiatives. Well-known organisations like the IAEA, WANO and European Commission also play a key role in gathering and providing access to knowledge and experience.

The EPZ organisation analyses this collective operating experience and assesses whether it is useful for its own operations. If, for example, an earthquake occurs in Japan, Japanese nuclear plants will provide an account of their experiences as quickly as possible. Borssele will then assess the impact on local nuclear plants and draw any lessons for its own situation.

Since 1990 the nuclear industry has been using the INES scale for reporting nuclear and radiological incidents at nuclear plants, and transport incidents or incidents with radioactive material in hospitals and other organisations. Just as the Richter scale is used to categorise earthquakes, the INES scale is used internationally to indicate the severity of disruptions at nuclear plants. There are seven levels on the INES scale, one to seven. Anything below that is categorised as INES=0, and has no safety significance.

INES ratings

The rating 0 is reserved for defects with no safety significance. INES ratings 1, 2 and 3 are referred to as incidents, which have no impact on staff or the surrounding area. At level 4, safety risks can occur within the plant, because of a release of radioactive substances within a building, for example. From level 5, an accident can have consequences for the immediate surroundings of the plant; 7 denotes a major accident whereby high levels of radioactive substances are released into the environment. Fukushima and Chernobyl were rated 7 on the INES scale.

Common technical faults

Typical faults that commonly occur are defects in the back-up safety systems that come to light during regular testing. Disruptions to operations causing energy generation to be halted for a short time can also occur. Finally, procedural failures may also be reported.

Responsibilities of EPZ and the authorities

EPZ investigates every fault to determine the cause, and how serious it is. On the basis of its own investigation, EPZ proposes the INES rating, and publishes all preliminary INES notifications.

It is however the authorities (the Authority for Nuclear Safety and Radiological Protection) that makes the final INES assessment on the basis of the EPZ report and its own investigation. The ANVS also ensures that improvements are carried out in response to disruptions. It reports every year to parliament on disruptions that have occurred at all nuclear plants in the Netherlands.

What happens after an INES notification?

At EPZ all work processes focus on preventing unsafe situations. The company records and analyses all operational experiences, including all disruptions and incidents, in accordance with international standards. Staff are also encouraged to report incidents internally, even if they seem insignificant. The purpose of this systematic, comprehensive approach is clear: to continuously improve safety, and to learn from mistakes.

EPZ is a member of the World Association of Nuclear Operators (WANO), an organisation to which almost all nuclear plants in the world are affiliated. WANO shares and analyses information about INES notifications and other irregularities. EPZ receives hundreds of reports each year which it analyses for their relevance to Borssele. EPZ also regularly sends reports to the global network itself.

Most notifications at Borssele are INES=0, with no significance for safety. The most serious incident (INES=2) was reported in 1996, when a valve was accidentally left open and went unnoticed for a while. Measures were taken to rule out the possibility of this ever happening again. The general trend at Borssele is downward: the number and severity of INES notifications fluctuates, but is on the decline. All INES notifications can be found on www.epz.nl.