Borssele is to remain in operation until 2034. EPZ has shown that it is in full control of the ageing of the plant. The plant will remain safe until 2034 and was granted an amended permit in 2013. The IAEA monitors ageing management.

Borssele will remain in operation longer than envisaged when it was constructed. It has been shown on the basis of international guidelines drawn up by the International Atomic Energy Agency (IAEA) in Vienna, with input from Dutch regulator ANVS, that safety is still assured. The IAEA organises special peer reviews of plants that are planning long-term operations. Borssele is regularly reviewed in this connection. In 2013 the permit allowing the plant to continue operating until 2034 was finalised.

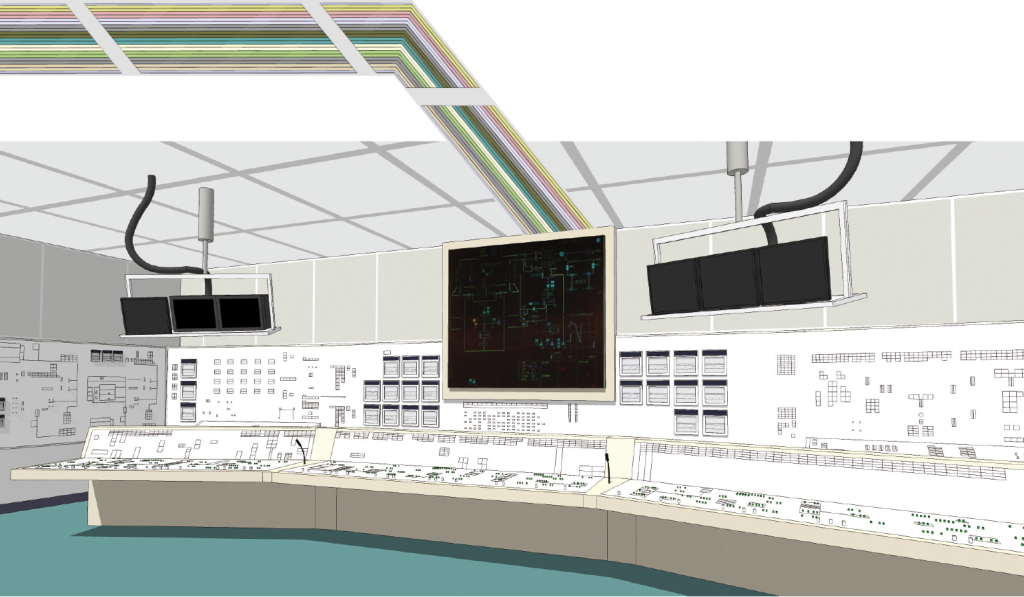

Ageing management at EPZ focuses both on technological ageing and on materials degradation. In time, materials degrade due to long-term use (physical ageing). In addition, technology is constantly evolving, and ‘old’ technology is no longer taught at colleges and universities. A plant may need to be modernised for either of these reasons. Now that Borssele is to remain in operation twenty years longer, measures have been taken to demonstrate that ageing can be managed up to 2034, with all the necessary safeguards. In many cases, this was a simple matter: the plant was designed to cope with much heavier loads than actually occur. In some cases, additional measurements and calculations have been performed. In all cases, EPZ demonstrated that the integrity of the components is guaranteed until at least 2034.

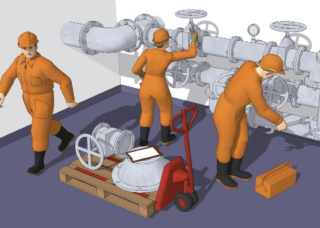

EPZ manages ageing with specific control measures: regular preventive maintenance, inspections to determine the status of components and, above all, operating the plant in such a way that physical ageing is kept to a minimum. Eventually, aged components are replaced.

An IAEA Ageing Management Assessment Team (AMAT) can visit EPZ to assess the situation at the request of the regulator (ANVS).

If necessary, AMAT can give suggestions as to how ageing management at EPZ can be improved even further.

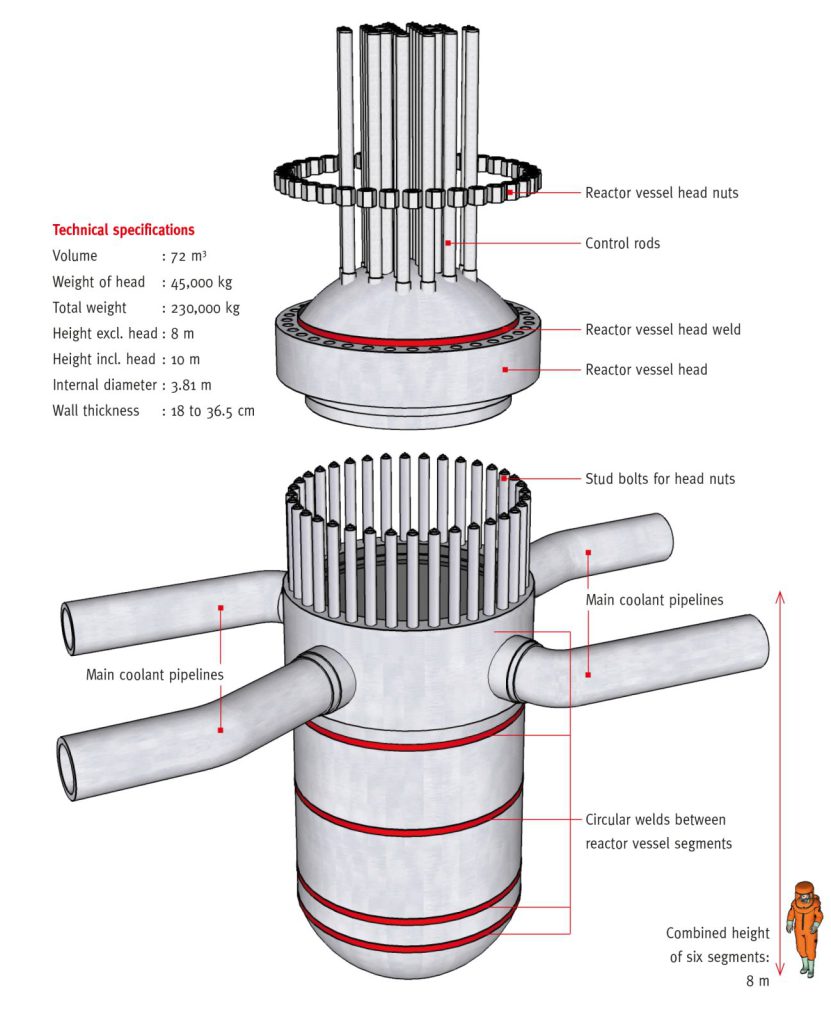

Since it is virtually impossible to replace the reactor vessel, its quality determines the lifespan of the entire nuclear plant. The vessel at Borssele – one of the best in the world – is made of high-quality steel that is 20 cm thick on average. The best materials available were used in its construction.

The impact of neutron radiation can cause a reactor vessel to lose its elasticity, posing a risk of fracture. EPZ is monitoring this process very closely. During maintenance work in 2010 steel samples were taken from the vessel. The results of the analysis can be used to determine how much neutron radiation the vessel has received to date.

The fact that Borssele is run at constant load operation means that there have been far fewer temperature fluctuations than envisaged. Clever management of the core has also ensured that there has been less neutron irradiation of the reactor vessel than assumed in its design. As a result, the plant can safely be kept in operation until 2034. If the load remains the same, the vessel could even last for more than a hundred years.

In 2012, in response to problems at Belgian nuclear plants, the quality of the steel at Borssele was thoroughly investigated. Even after forty years of production, it is better than would be required of a new plant.

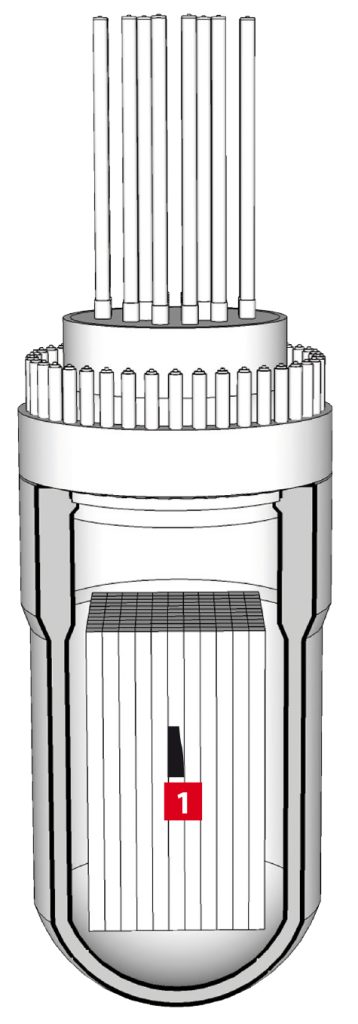

In 2007, non-irradiated test rods [1] from the reactor vessel were placed around the core. Here, extra high neutron and temperature loads cause accelerated ageing. This test will end in 2018, and the results should allow EPZ to demonstrate that the reactor vessel can be used safely until 2034, and possibly longer.

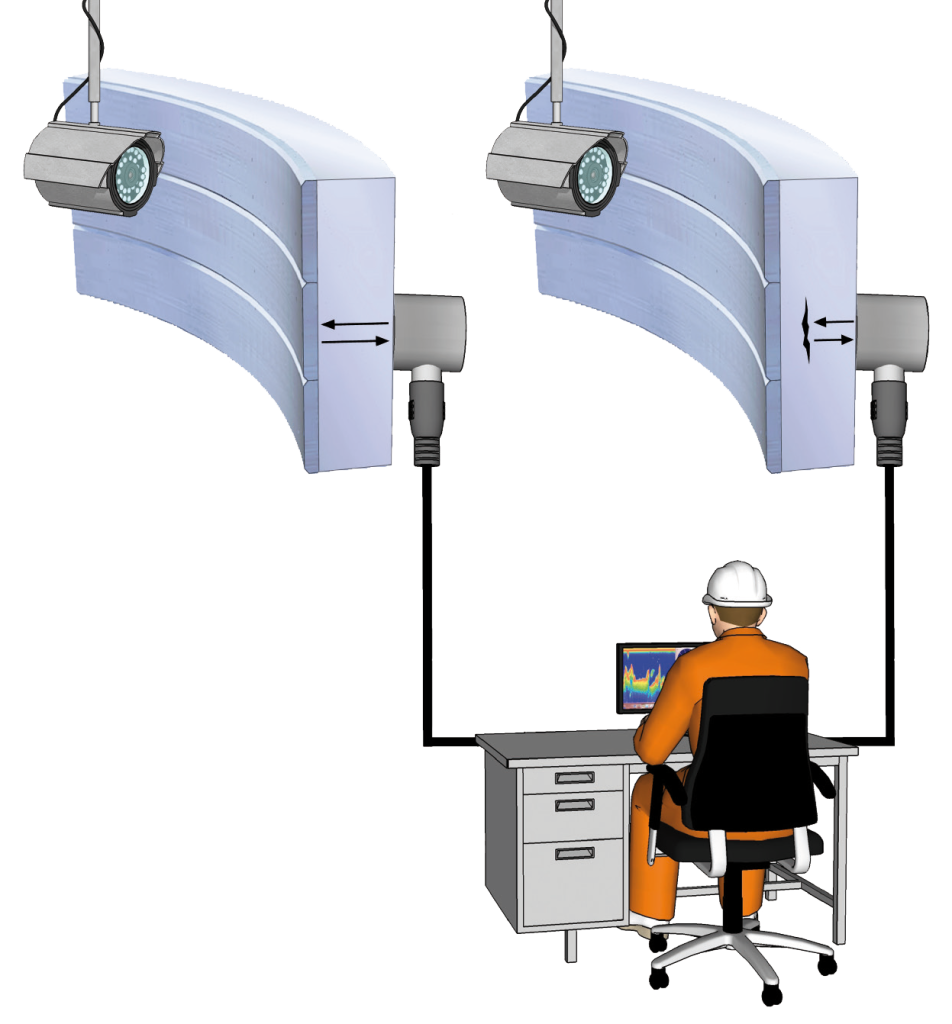

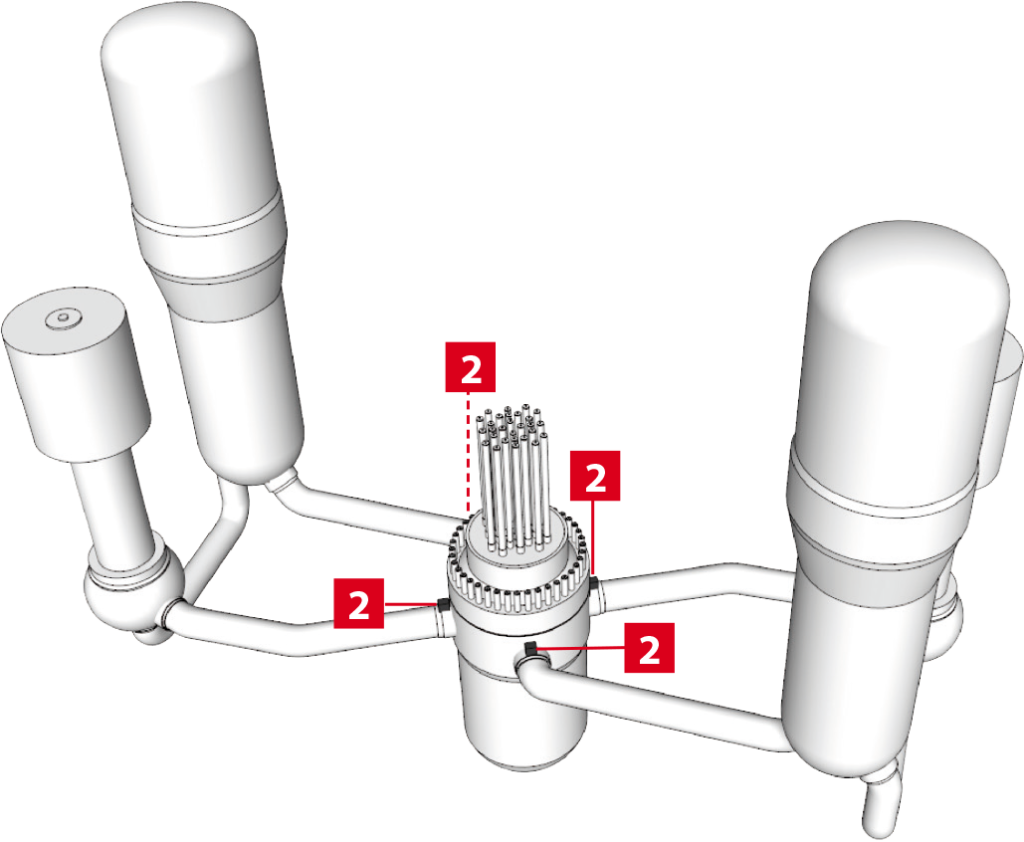

The primary circuit cools the core. If a pipe breaks, the core will no longer be cooled. To prevent this from happening, welds and joins between different materials are inspected annually using ultrasound and x-rays.

In 1997 ‘leak-before-break’ measures were taken to exclude the risk of pipe breaks. If a pipe degrades, a leak will occur which will be detected using a special leak detection system. The plant can then be safely closed down. Even though the possibility of a pipe break has been ruled out by the ‘leak-before-break’ measures, the plant is designed in such a way that, if a break were to appear, reactor shutdown and core cooling are ensured.

Vital points in the primary circuit are being monitored by thermocouples [2] since 2010. They record any load changes as a result of changes in temperature. The data can be used to draw ‘real-time’ conclusions about fatigue in the primary circuit.

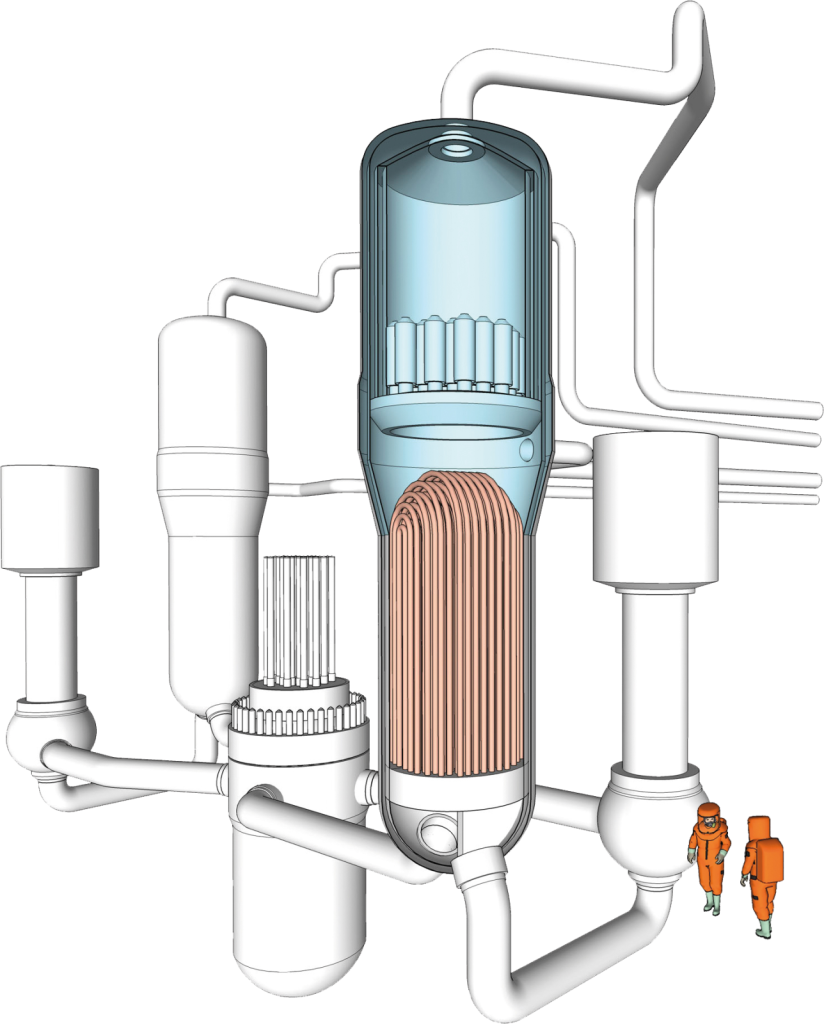

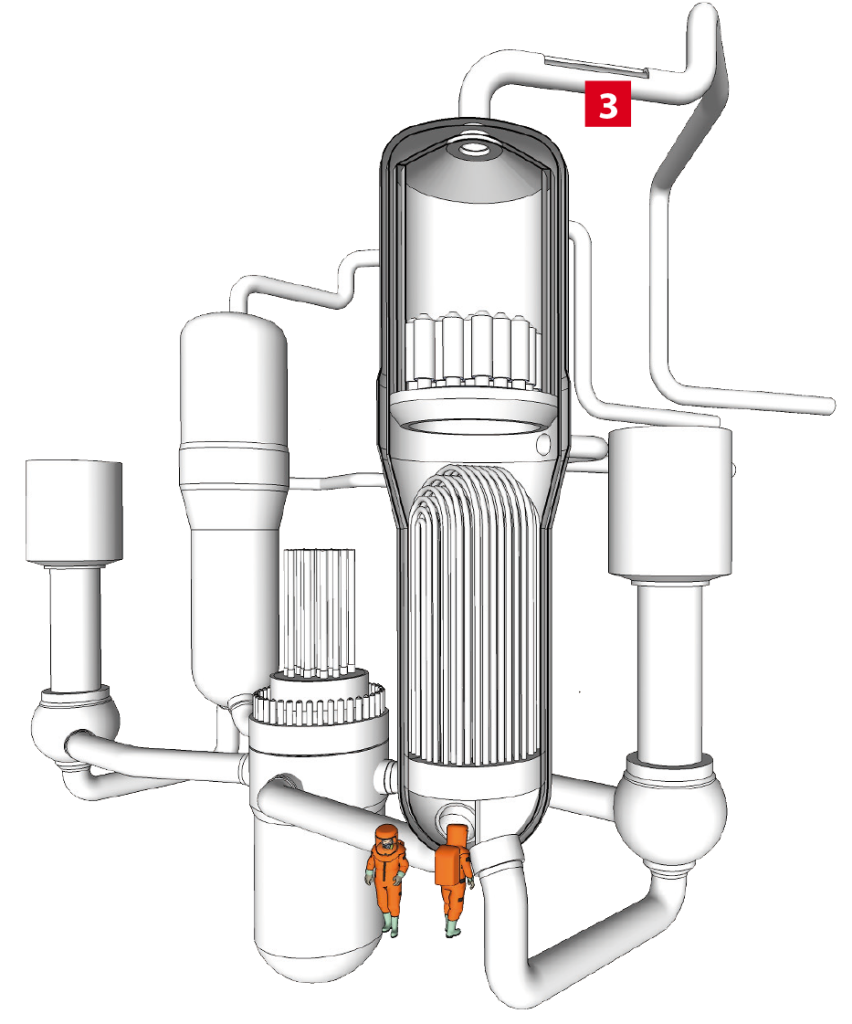

In the steam generator the primary heat is transferred to the steam cycle which generates electricity. Thousands of tubes transfer the primary heat to the secondary system. A majority of the tubes are individually inspected once every three years. If any major defects are found, the tubes are capped and others take over their job. The steam generator at Borssele is overdimensioned, and the margin is more than enough to continue operations until 2034.

The two steam generators are also among the best in the world. The steam generators in most pressurised water reactors have been replaced, or are due to be replaced, because of cracking due to primary water stress corrosion. These cracks form under the influence of primary water in the steam generator tubes, which are made of a nickel alloy. In most nuclear power plants, the pipes are made of Inconel 600, which has been found to be susceptible to water stress corrosion. The steam generators at Borssele are made of Incoloy 800, however, which is not susceptible to primary water stress corrosion cracking.

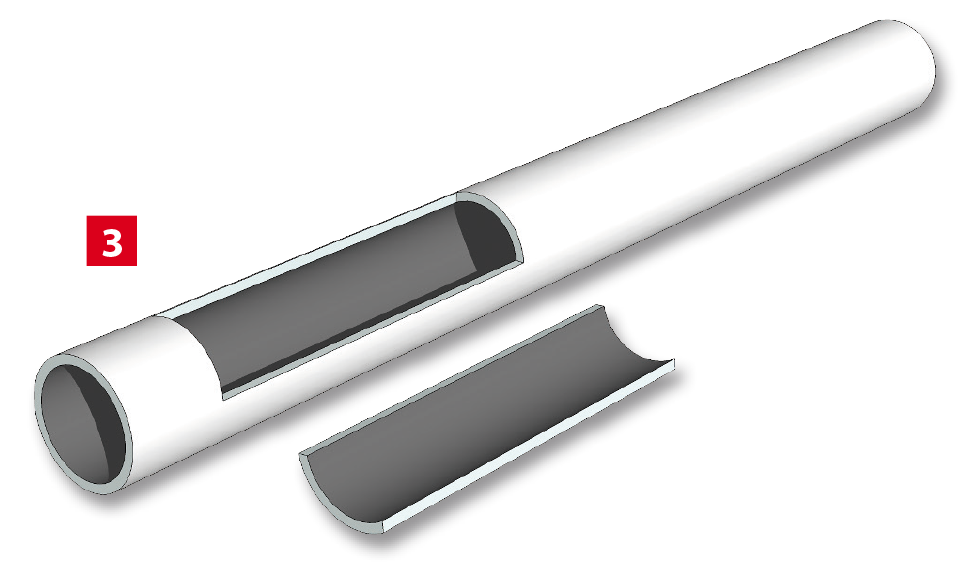

To prevent corrosion in the secondary (non-nuclear) systems, demineralised water containing chemical additives is used in the water/steam cycle. Phosphate chemicals were used originally, but they raised the probability of damage to the tubes in the steam generator [3].

Once the steel condensers were replaced with titanium, it was possible to switch to All Volatile Treatment (AVT) chemicals. This halted the corrosion process in the steam generators, as regular extensive inspections of the tubes have shown.